The DLM platform is a completely new product development and a pilot project focused on optimizing transport logistics and route planning with real-time data tracking. It calculates the most efficient delivery routes, adjusts to traffic or disruptions, and provides contingency plans to ensure smooth operations. The system also manages trucks, drivers, and shuttle schedules, streamlining daily transport planning for logistics professionals.

Identified industry and user need

Comprehensive design system,

Mapped out workflows,

Designing from scratch,

Criteria to prevent errors

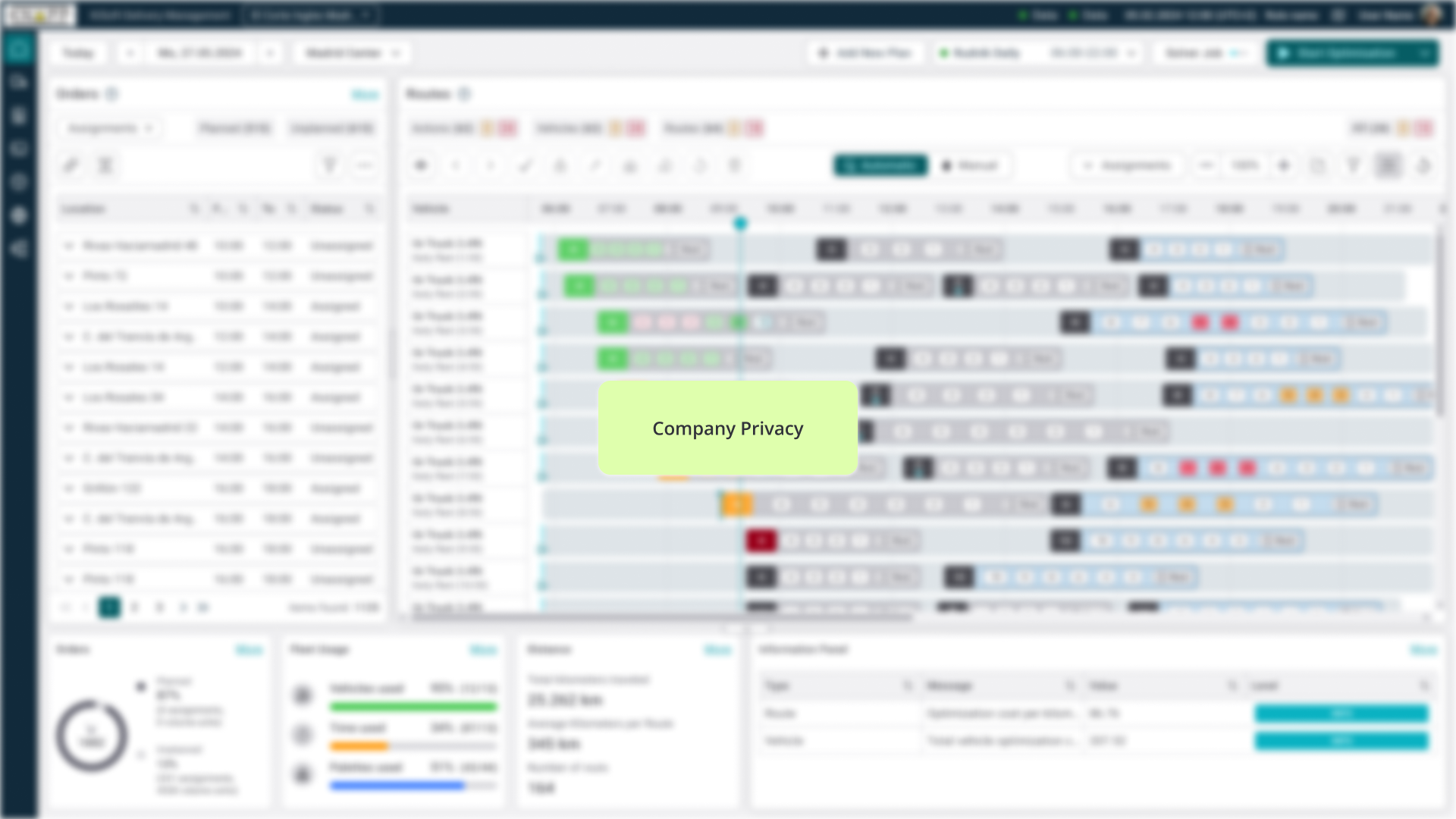

The platform solves the challenge of managing and coordinating complex delivery operations involving multiple trucks and fleets. Before, there was no clear, centralized way to assign orders, schedule departures, and track deliveries in real time, which made logistics inefficient and hard to oversee.

The platform serves industries like food production, manufacturing, and ironworks or other sectors with a warehouse where precision and efficiency are critical. The design emphasizes functionality and clarity to support high-stakes logistics operations.

The typical user is a logistics coordinator in a warehouse, usually one or two people responsible for managing daily transport operations. This person is detail-oriented and highly organized, constantly juggling schedules, routes, and unexpected delivery issues. They think ahead to avoid delays, solve problems quickly when things go wrong, and keep track of multiple trucks and orders at once. They rely on clear, straightforward information to make fast decisions and ensure everything runs smoothly from the warehouse to the final destination. Their day is busy, often under pressure, and they need a tool that helps them stay in control without added confusion.

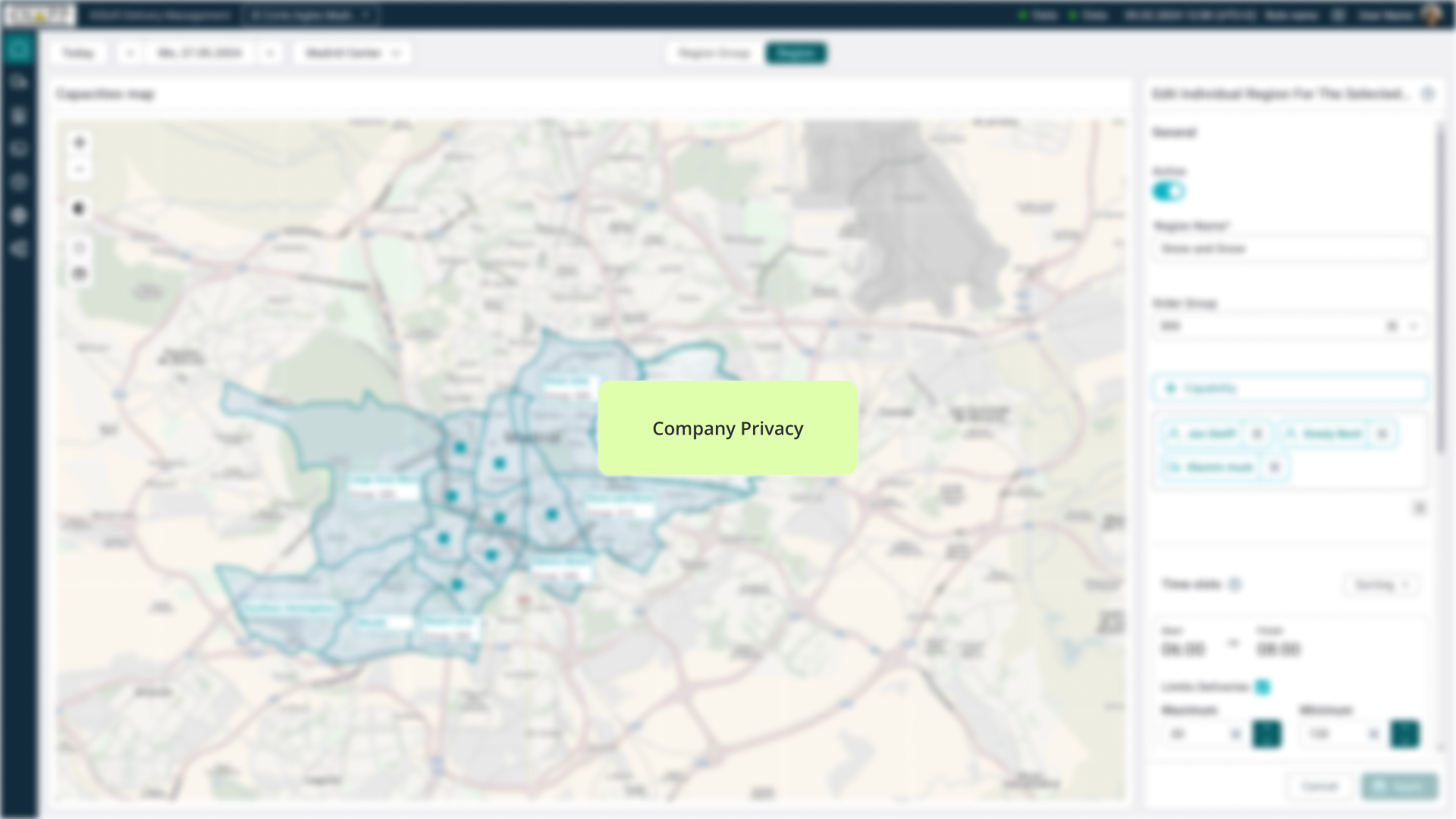

I worked closely with a logistics expert to break down daily tasks and understand how they connect. We focused on task-based flows like assigning trucks, planning routes, and reacting to delays. We mapped these actions to see how they influence each other and built the platform around these real workflows. The aim was to support both regular planning and quick reactions when things go off track.

Planners focus on completing real-world tasks like assigning drivers, creating delivery routes, or adjusting time slots, not on clicking features. During research, I saw users naturally group actions around goals, so we built flows that support those tasks directly instead of splitting them across multiple tools.

When delays, reroutes, or driver issues happen, users need to respond fast. I found that confusion often came from unclear alerts or hidden consequences. The system was redesigned to show clear status changes and provide instant access to alternative actions when plans shift.

Planners often need to understand how one change affects others, like moving one delivery pushing others into overtime. I identified that these connections weren’t visible before. The new platform shows task dependencies clearly and lets users adjust them with minimal friction, reducing planning errors.

The design centres around a main gantt chart that shows all routes and orders in one place. Along with this, there are other screens like Maps to see locations and separate screens with detailed order information. All these screens work together smoothly, giving users a complete view of the transport process. To support this, I created a design component library that ensures consistency and makes the system easy to use across multiple screens.

Users set up essential data (vehicles, drivers, working hours, pick-up locations) and create daily transport plans with delivery details. The system optimizes routes and presents data visually via a central Gantt chart, enabling users to monitor timelines, track progress, and manage orders efficiently.